Overview

Electrode rolling is a critical manufacturing step in lithium ion battery production, serving as the bridge between electrode coating and cell assembly. This process involves compressing the coated electrode material between two rotating rollers to achieve precise thickness, density, and surface characteristics.

The quality of the rolling process directly impacts the final battery performance, including energy density, cycle life, and safety. This is particularly true for specialized applications such as the lithium ion marine battery, where reliability and performance under harsh conditions are paramount.

Modern rolling technology combines mechanical precision with advanced control systems to ensure uniform compression across the entire electrode surface. The development of high-precision rolling equipment has been instrumental in the evolution of battery technology, enabling the production of thinner, denser electrodes that contribute to higher energy densities.

In the context of the lithium ion marine battery, electrode rolling takes on additional significance due to the unique demands of marine environments. These batteries must withstand vibration, temperature fluctuations, and potential mechanical stress, making consistent electrode quality through precise rolling absolutely essential.

The rolling process must be carefully optimized for each electrode formulation and application. Variables such as roller pressure, speed, temperature, and material properties must be precisely controlled to achieve the desired electrode characteristics. This overview will be expanded through the subsequent sections, providing a comprehensive understanding of each aspect of electrode rolling technology.

Electrode Manufacturing Process Flow

- Slurry preparation and mixing

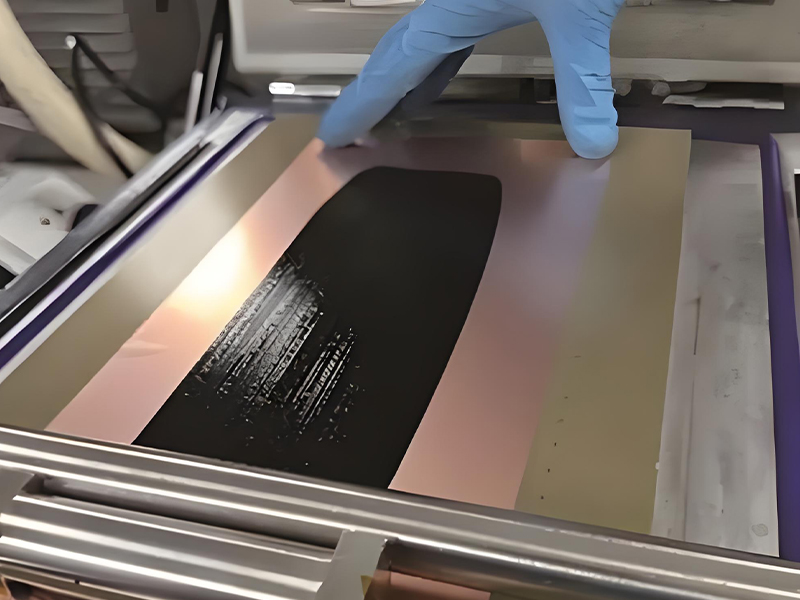

- Electrode coating on current collector

- Rolling/pressing of coated electrode

- Drying and solvent removal

- Electrode slitting and cutting

- Cell assembly and packaging

Rolling is a critical intermediate step that determines final electrode density, which directly affects the performance of all lithium ion batteries, including the specialized lithium ion marine battery.

Powder Basic Properties

The performance of rolled electrodes is fundamentally influenced by the basic properties of the active material powders used in the electrode formulation. These properties include particle size distribution, specific surface area, particle shape, tap density, and flowability.

Particle size distribution (PSD) significantly affects both processing and final battery performance. For applications like the lithium ion marine battery, where consistency is critical, a narrow PSD ensures uniform packing during rolling, leading to consistent electrode density. Particles that are too large can create voids, while excessively fine particles may increase resistance and processing difficulties.

Specific surface area (SSA) impacts both the electrochemical performance and the rolling behavior. Higher SSA provides more reaction sites but requires more binder and can increase electrode resistance if not properly compressed. During rolling, powders with higher SSA typically require more pressure to achieve target densities.

Particle shape influences packing efficiency and rolling characteristics. Spherical particles generally pack more uniformly and require less pressure to densify compared to irregular or plate-like particles. This is particularly important for the lithium ion marine battery, where uniform current distribution is essential for safety and longevity.

Tap density, the density achieved after mechanical tapping, provides a baseline for the maximum achievable density during rolling. It correlates with the theoretical maximum density (TMD) of the material, which is typically 80-90% for most electrode materials after optimized rolling.

Flowability, often measured by angle of repose, affects the coating process prior to rolling. Poorly flowing powders can cause uneven coating, which then leads to challenges during rolling, as uniform compression becomes difficult. For high-performance applications like the lithium ion marine battery, consistent powder flow is essential for maintaining electrode quality and performance.

Key Powder Properties and Their Impact

Particle Size

Affects packing density and reactivity. Optimal range: 1-20μm for most cathode materials used in lithium ion marine battery applications.

Surface Area

Higher surface area increases reaction sites but requires careful rolling to manage electrical resistance.

Particle Shape

Spherical shapes provide better packing efficiency and more uniform rolling results.

Moisture Content

Critical for processing; excessive moisture can cause issues during rolling and affect final battery performance, especially in lithium ion marine battery systems.

Powder Packing Model and Packing Density

Powder packing models help predict and optimize the density achievable during electrode rolling. These models consider particle size, shape, and distribution to determine the maximum possible packing efficiency under different compression conditions.

The random close packing (RCP) model is commonly used to describe the packing behavior of spherical particles, predicting a maximum packing density of approximately 64%. However, in practical electrode manufacturing, especially for high-performance applications like the lithium ion marine battery, densities often exceed this due to particle deformation during rolling.

Binary and ternary packing models, which incorporate particles of different sizes, have proven more accurate for real-world electrode materials. These models show that incorporating smaller particles to fill the voids between larger ones can significantly increase packing density. This principle is widely applied in lithium ion marine battery production to maximize energy density.

Packing density is typically expressed as a percentage of the theoretical maximum density (TMD) of the material. For most cathode materials, rolling processes aim to achieve 80-90% of TMD. Anode materials, due to their different mechanical properties, often reach 75-85% of TMD after rolling.

The relationship between applied pressure during rolling and achieved density follows a sigmoidal curve. Initially, density increases rapidly with pressure as voids are eliminated. Beyond a certain point, further pressure increases result in diminishing returns, with density approaching a plateau.

For the lithium ion marine battery, which requires both high energy density and mechanical robustness, optimizing packing density is a balancing act. Higher densities increase energy storage capacity but can reduce ionic conductivity and mechanical flexibility. Advanced packing models help manufacturers determine the optimal density for specific marine applications, considering factors like vibration resistance and charge-discharge cycles.

Powder Packing Configurations

Different particle arrangements affect packing efficiency and ultimately the performance of rolled electrodes in applications such as the lithium ion marine battery.

Density vs. Pressure Relationship

The curve shows typical density achieved versus applied pressure during rolling, with distinct regions of rapid density increase and eventual plateau. This relationship is carefully calibrated for lithium ion marine battery production to balance energy density and mechanical properties.

Actual Powder Compression Performance

Actual powder compression performance during rolling is influenced by a complex interplay of material properties, equipment parameters, and environmental conditions. Unlike idealized models, real-world compression involves particle rearrangement, deformation, and sometimes even fracture under the applied roller pressure.

For cathode materials like NCM (nickel-cobalt-manganese) and LFP (lithium iron phosphate) commonly used in the lithium ion marine battery, compression behavior varies significantly. NCM particles tend to deform more readily under pressure, allowing higher packing densities, while LFP particles are more rigid and require higher pressures to achieve similar densities.

Anode materials, typically graphite-based, exhibit different compression characteristics due to their layered structure. Graphite can undergo both particle rearrangement and layer alignment during rolling, which affects both density and electrical conductivity. This is particularly important for the lithium ion marine battery, where consistent electrical performance under varying conditions is critical.

The compression process can be divided into three distinct phases: initial compaction, where particles move to fill voids; elastic deformation, where particles temporarily change shape; and plastic deformation, where permanent shape changes occur. The transition between these phases varies by material and significantly impacts the rolling parameters chosen for different battery types.

Compression rate, or the speed at which rollers apply pressure, also affects performance. Higher speeds may reduce density achieved due to insufficient particle rearrangement time, while very low speeds reduce production efficiency. For the lithium ion marine battery, which often uses thicker electrodes for higher capacity, optimal compression rates are typically lower to ensure uniform density through the electrode thickness.

Post-compression relaxation is another important consideration. Many materials exhibit spring-back, where the electrode thickness increases slightly after rolling pressure is removed. This effect must be accounted for in process design to achieve the target final dimensions. In lithium ion marine battery production, where dimensional consistency is critical for stack or winding processes, precise control of this relaxation effect is essential.

Compression Behavior of Common Electrode Materials

Key Compression Parameters

These parameters are typically adjusted based on specific material properties and performance requirements, with tighter tolerances applied for critical applications such as the lithium ion marine battery.

Electrode Rolling Principles and Processes

Electrode rolling operates on the fundamental principle of applying controlled pressure to the coated electrode material through a pair of counter-rotating rollers. This process reduces the electrode thickness while increasing its density, achieving the desired physical and electrochemical properties.

The basic rolling process involves feeding the coated electrode between two parallel rollers that rotate at the same speed but in opposite directions. The gap between the rollers is precisely controlled to determine the final thickness of the electrode. As the electrode passes through the nip (the point where the rollers are closest), pressure is applied, compressing the active material layer.

Modern rolling systems employ either rigid or compliant rollers. Rigid rollers, typically made of hardened steel, provide high precision for thin electrodes used in high-energy applications. Compliant rollers, which have a flexible surface layer, are better suited for thicker electrodes or those with potential coating irregularities, making them valuable in lithium ion marine battery production where electrode thickness may be greater.

Two primary rolling processes are used in battery manufacturing: cold rolling and warm rolling. Cold rolling is performed at ambient temperature and is the most common method for standard battery production. Warm rolling, conducted at elevated temperatures (typically 40-120°C), can improve density uniformity and reduce spring-back, particularly beneficial for the lithium ion marine battery where dimensional stability is critical.

The rolling process can be configured as either a single-pass or multi-pass operation. Single-pass rolling achieves the desired thickness reduction in one pass, offering higher production rates. Multi-pass rolling uses multiple roller pairs with progressively decreasing gaps, reducing stress on the electrode and providing better control over density distribution. This latter method is often preferred for high-performance electrodes in applications like the lithium ion marine battery.

Advanced rolling systems incorporate real-time monitoring and feedback control, adjusting roller pressure and gap dynamically to maintain consistent thickness and density. This level of control is essential for meeting the stringent quality requirements of the lithium ion marine battery, where even minor variations can affect performance and safety in demanding marine environments.

Rolling Process Dynamics

The diagram illustrates the key components of a modern electrode rolling system, highlighting the pressure distribution and material flow during the process.

Roller Alignment

Micron-level precision ensures uniform pressure across the electrode width

Speed Synchronization

Precise speed control prevents material stretching or wrinkling

Pressure Profiling

Variable pressure zones optimize density across complex electrode designs

Rolling Process Comparison

| Process Type | Advantages | Best For |

|---|---|---|

| Cold Rolling | Lower energy, simpler equipment | Standard production, thin electrodes |

| Warm Rolling | Higher density, better uniformity | Lithium ion marine battery, high-performance cells |

| Single-pass | Higher throughput | Large volume production |

| Multi-pass | Better density control, less stress | Thick electrodes, lithium ion marine battery |

Rolled Cathode and Battery Performance

The rolling process has a profound impact on final battery performance, with direct correlations between electrode density, uniformity, and key battery metrics such as energy density, cycle life, rate capability, and safety. This relationship is particularly critical for specialized applications like the lithium ion marine battery, where performance parameters must meet stringent operational requirements.

Energy density, a primary performance metric for any battery, increases with electrode density up to an optimal point. Beyond this point, further density increases can restrict ion diffusion pathways, reducing performance. For the lithium ion marine battery, which requires maximum energy storage in limited space, finding this optimal density balance is essential.

Cycle life, the number of charge-discharge cycles a battery can undergo before significant capacity loss, is significantly influenced by rolling quality. Uniform density distribution minimizes local stress during volume changes associated with lithium ion insertion and extraction. This is particularly important for the lithium ion marine battery, which often operates in deep-cycle applications requiring hundreds or thousands of cycles.

Rate capability, the ability to deliver high current, is affected by both electrode density and porosity. Higher density reduces ionic conductivity, while lower density limits energy storage. Advanced rolling techniques can create a gradient density structure, with higher density near the current collector for structural support and lower density near the electrode surface to facilitate ion transport – an approach increasingly used in lithium ion marine battery designs.

Thermal performance is another critical factor influenced by rolling. Uniform density ensures consistent current distribution, reducing hot spots that can lead to thermal runaway. For the lithium ion marine battery, which may operate in extreme temperature environments, maintaining stable thermal performance through proper rolling is a key safety consideration.

Mechanical robustness, often overlooked but essential for the lithium ion marine battery, is directly impacted by rolling. Properly compacted electrodes exhibit better resistance to vibration and mechanical stress encountered in marine environments. The rolling process also affects electrode adhesion to the current collector, reducing the risk of delamination and capacity fade over time.

Impact of Rolling Parameters on Battery Performance

Key Performance Metrics by Density

Energy Density

Increases with density up to optimal point (~85% TMD for most cathode materials used in lithium ion marine battery applications)

Cycle Life

Peaks at moderate densities with good uniformity, critical for lithium ion marine battery longevity

Rate Capability

Decreases with higher density due to reduced ionic pathways

Mechanical Strength

Increases with density, important for vibration resistance in lithium ion marine battery applications

Electrode Rolling Equipment

Electrode rolling equipment has evolved significantly to meet the demanding requirements of modern lithium ion battery production, including the specialized needs of the lithium ion marine battery sector. These sophisticated machines combine mechanical precision with advanced control systems to achieve the tight tolerances required for high-performance electrodes.

The core component of any rolling system is the roller assembly, which consists of two parallel rollers mounted in a rigid frame. Rollers are typically constructed from high-strength alloy steel with precision-ground surfaces to ensure uniform pressure distribution. For specialized applications like the lithium ion marine battery, roller surfaces may feature advanced coatings to reduce friction and prevent material buildup.

Modern rolling machines incorporate servo-hydraulic or servo-electric systems to control roller gap and applied pressure with micron-level precision. These systems can apply pressures ranging from 5 to 50 MPa, with advanced models offering zone-specific pressure control across the roller width to compensate for edge effects or coating variations.

Web handling systems are critical for maintaining proper tension and alignment of the electrode material as it passes through the rollers. These systems include unwinding and rewinding stations, tension control devices, and edge guiding mechanisms. For lithium ion marine battery production, which often uses wider electrodes than consumer electronics, robust web handling is particularly important.

Inline measurement systems have become standard features in advanced rolling equipment, providing real-time feedback on electrode thickness, density, and uniformity. Laser or ultrasonic sensors continuously monitor the rolled electrode, sending data to the control system which adjusts roller parameters dynamically to maintain specifications. This closed-loop control is essential for meeting the consistency requirements of the lithium ion marine battery.

Specialized rolling equipment for the lithium ion marine battery may include additional features such as temperature-controlled rollers for warm rolling processes, larger roller diameters to handle thicker electrodes, and enhanced dust collection systems to maintain cleanliness. These machines are often integrated into complete electrode manufacturing lines, with automated material handling and data logging capabilities to ensure traceability – a key requirement for marine safety certifications.

Rolling Equipment Components

Modern rolling machines integrate multiple subsystems to achieve precise control over the electrode rolling process, with specialized configurations available for lithium ion marine battery production.

Precision Rollers

±1μm surface finish, alloy steel construction

Pressure Control

Servo-hydraulic with ±0.1 MPa accuracy

Thickness Measurement

Laser sensors with ±0.1μm resolution

Tension Control

Closed-loop with 0.1% accuracy

Equipment Specifications Comparison

| Specification | Standard Equipment | Marine Battery Equipment |

|---|---|---|

| Max Electrode Width | 300-600 mm | 600-1200 mm |

| Thickness Control | ±1μm | ±0.5μm |

| Max Pressure | 30 MPa | 50 MPa |

| Temperature Control | Optional | Standard (RT-150°C) |

| Data Logging | Basic | Comprehensive (ISO 9001 compliant) |

Electrode Quality and Control

Electrode quality control is a critical aspect of the rolling process, ensuring that the final product meets the stringent performance and safety requirements of lithium ion batteries, particularly for demanding applications like the lithium ion marine battery. Quality control encompasses both inline monitoring during rolling and offline inspection of finished electrodes.

Thickness uniformity is one of the most important quality parameters, with modern systems requiring variations of less than ±1% across the electrode width and length. For the lithium ion marine battery, which often uses large-format electrodes, maintaining this uniformity is particularly challenging but essential for preventing localized heating and ensuring consistent performance.

Density measurement and control provide direct insight into the electrochemical performance of the electrode. Methods include destructive testing of sample coupons, where thickness and mass are measured to calculate density, and non-destructive techniques such as X-ray or beta-ray gauging that can be integrated into the rolling line for real-time monitoring. For lithium ion marine battery production, 100% inline density monitoring is increasingly becoming a standard practice.

Surface quality assessment includes checking for defects such as cracks, pinholes, and roller marks that can compromise performance. Automated optical inspection systems use high-resolution cameras and machine learning algorithms to detect these defects with high accuracy, ensuring that only flawless electrodes proceed to cell assembly – a requirement that is especially stringent for the lithium ion marine battery.

Adhesion strength between the active material layer and current collector is another critical quality parameter affected by rolling. Excessive pressure can reduce adhesion, while insufficient pressure may result in poor conductivity. Peel tests are commonly used to verify adhesion, with specifications tailored to the specific battery application. For the lithium ion marine battery, which may experience vibration and mechanical stress, adhesion requirements are typically more demanding.

Statistical process control (SPC) is employed to monitor all critical parameters, identifying trends and variations before they result in quality issues. For the lithium ion marine battery, which must meet rigorous industry standards and certifications, comprehensive SPC with traceability of every electrode is mandatory. This level of quality control ensures that each lithium ion marine battery meets the performance and safety requirements for reliable operation in harsh marine environments.Electronic shelf labels.

Electrode Quality Control Parameters

Quality Assurance Methods

Inline Process Monitoring

- • Laser thickness gauging (±0.1μm resolution)

- • X-ray density measurement

- • Optical surface inspection (100% coverage)

- • Tension and speed monitoring

Offline Testing

- • Density verification via weight/volume measurement

- • Peel strength testing for adhesion

- • Cross-sectional analysis for uniformity

- • Electrochemical performance testing

Special Requirements for Lithium Ion Marine Battery

- • Enhanced inspection for vibration resistance

- • Extended temperature range testing

- • Full traceability documentation

- • Compliance with marine safety standards