Lithium ion batteries have revolutionized portable electronics, electric vehicles, and renewable energy storage systems. Their performance, energy density, and longevity directly depend on the quality and characteristics of their constituent materials. Understanding these materials is crucial for advancing battery technology and addressing safety concerns such as lithium ion battery fire risks.

This comprehensive guide examines the five primary categories of materials used in lithium ion batteries, exploring their properties, manufacturing processes, and roles in overall battery performance and safety. Each section includes detailed information on how these materials contribute to battery efficiency while addressing potential lithium ion battery fire hazards through proper material selection and engineering.

Cathode Materials

The Cathode Materials are the positive electrodes in lithium ion batteries and play a critical role in determining energy density, voltage, and overall performance. These materials are typically metal oxides containing lithium, which can intercalate and deintercalate lithium ions during charge and discharge cycles. The choice of cathode material significantly impacts not only performance but also safety, including the risk of lithium ion battery fire under extreme conditions.

Lithium cobalt oxide (LiCoO₂) was the first commercially successful cathode material, offering high energy density and stable performance. However, its relatively high cost and safety concerns—rooted in lithium ion battery chemistry (e.g., increased risk of lithium ion battery fire when the material’s crystal structure is disrupted by damage or overcharging)—have led to the development of alternative formulations.

Lithium nickel manganese cobalt oxides (NMC) combine nickel, manganese, and cobalt in varying proportions, offering a balance of energy density, stability, and cost. These materials have become popular in electric vehicles due to their improved safety profile compared to LCO, reducing the likelihood of lithium ion battery fire incidents during normal operation.

Lithium iron phosphate (LiFePO₄ or LFP) has gained significant attention for its enhanced safety characteristics, making it less prone to thermal runaway and lithium ion battery fire events even under abuse conditions. While offering lower energy density than NMC, LFP cathodes provide longer cycle life and better thermal stability, making them ideal for applications where safety is paramount.

Other cathode materials include lithium manganese oxide (LMO), lithium nickel cobalt aluminum oxide (NCA), and various doped and modified formulations. Each material presents a unique set of trade-offs between energy density, power output, cycle life, cost, and safety regarding lithium ion battery fire risks.

Manufacturers continuously research new cathode compositions and structures to improve performance while addressing safety concerns. Coating technologies, particle engineering, and doping strategies are employed to enhance thermal stability and reduce the potential for lithium ion battery fire incidents, even under extreme operating conditions.

Cathode Material Comparison

Performance comparison of common cathode materials, including safety ratings related to lithium ion battery fire risk.

Anode Materials

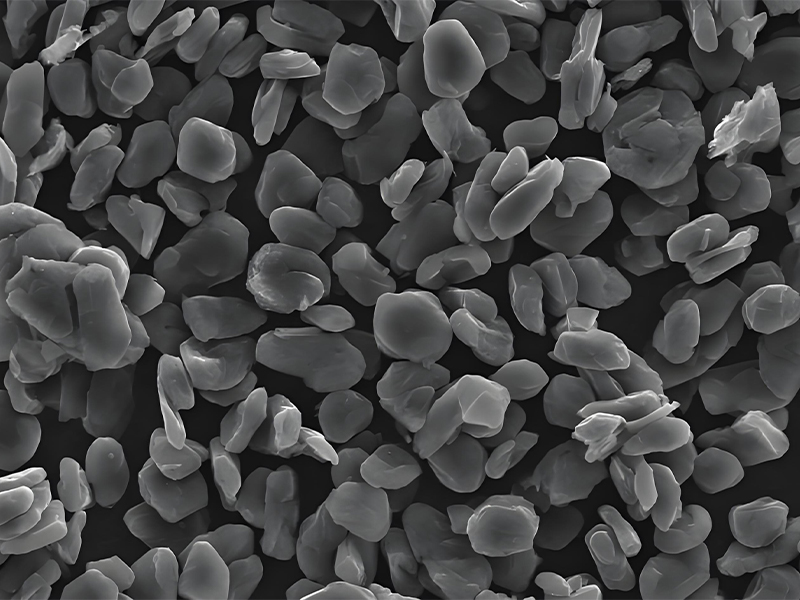

Anode Materials serve as the negative electrode in lithium ion batteries, storing lithium ions during charging and releasing them during discharge. The most commonly used anode material is graphite, which offers excellent lithium intercalation properties, high conductivity, and good cycle stability. Graphite's structure helps prevent dendrite formation, which can cause short circuits and potentially lead to lithium ion battery fire incidents.

Natural graphite and synthetic graphite are both used in battery production, with synthetic varieties often providing better performance characteristics but at higher cost. The graphite anode's layered structure allows lithium ions to intercalate between carbon layers without significant volume change, contributing to battery stability and reducing lithium ion battery fire risks.

Silicon is a promising alternative anode material due to its extremely high theoretical capacity—approximately 10 times that of graphite. However, silicon undergoes significant volume expansion (up to 300%) during lithium insertion, which can lead to electrode degradation and potential safety issues, including increased risk of lithium ion battery fire due to structural instability.

Researchers are developing silicon-carbon composites and nanostructured silicon materials to mitigate volume expansion issues. These advanced anode materials aim to retain silicon's high capacity while maintaining structural integrity, which is crucial for preventing lithium ion battery fire incidents in high-performance applications.

Other emerging anode materials include tin, germanium, titanium oxides, and various metal organic frameworks. Each of these materials presents unique challenges in terms of volume stability, conductivity, and manufacturing complexity, all of which can impact battery safety and the potential for lithium ion battery fire events.

The interface between the anode and electrolyte, known as the solid electrolyte interphase (SEI), plays a critical role in battery performance and safety. A stable SEI layer prevents continuous electrolyte decomposition and reduces the risk of short circuits that could lead to lithium ion battery fire incidents. Anode material selection and surface treatment significantly influence SEI formation and stability.

Anode Material Properties

Graphite

- Excellent cycle stability

- Low volume change

- Good safety profile

- Moderate capacity

Silicon

- Very high capacity

- Abundant material

- High volume expansion

- Potential lithium ion battery fire risk

Tin

- High capacity

- Good conductivity

- Volume expansion issues

- Limited cycle life

Titanium Oxide

- Excellent safety

- No lithium ion battery fire risk

- Long cycle life

- Low energy density

Electrolytes

Electrolytes facilitate the movement of lithium ions between the cathode and anode during charge and discharge cycles. Traditional electrolytes consist of lithium salts dissolved in organic solvents, which provide high ionic conductivity but present safety challenges, including flammability that can contribute to lithium ion battery fire incidents when exposed to high temperatures.

Common lithium salts used in electrolytes include lithium hexafluorophosphate (LiPF₆), lithium tetrafluoroborate (LiBF₄), and lithium perchlorate (LiClO₄). LiPF₆ is most widely used due to its excellent conductivity and stability with electrode materials, though it can decompose at high temperatures, potentially releasing toxic gases and contributing to lithium ion battery fire risks.

Organic solvents in liquid electrolytes are typically carbonates such as ethylene carbonate (EC), propylene carbonate (PC), dimethyl carbonate (DMC), and diethyl carbonate (DEC). These solvents are chosen for their ability to dissolve lithium salts and wet electrode surfaces, but their flammability is a major safety concern in relation to lithium ion battery fire hazards.

To address safety issues, researchers have developed flame-retardant additives and non-flammable co-solvents that can reduce electrolyte flammability without significantly compromising performance. These advancements help mitigate lithium ion battery fire risks while maintaining the necessary ionic conductivity for efficient battery operation.

Solid-state electrolytes represent a major innovation in electrolyte technology, offering the potential to eliminate liquid flammable components entirely. These materials can be polymers, ceramics, or composite materials, and they provide improved safety by preventing electrolyte leakage and significantly reducing lithium ion battery fire risks.

Polymer electrolytes, typically based on polyethylene oxide (PEO) or polyacrylonitrile (PAN), offer good flexibility and ease of processing but generally have lower ionic conductivity than liquid electrolytes at room temperature. Ceramic electrolytes, such as lithium garnets and perovskites, provide high ionic conductivity and excellent thermal stability, making them highly resistant to lithium ion battery fire incidents, but they can be brittle and challenging to integrate into battery designs.

The development of advanced electrolytes with high conductivity, wide electrochemical stability windows, and superior thermal stability remains a key area of research to enhance battery performance while minimizing lithium ion battery fire risks in various applications.

Electrolyte Technology Comparison

Electrolyte flammability is a critical factor in lithium ion battery fire risk. Solid-state electrolytes show the most promise for reducing this risk while maintaining performance.

Separators

Separators are critical components in lithium ion batteries that physically separate the cathode and anode while allowing the transport of lithium ions, a key consideration in lithium ion battery packaging. This separation prevents direct electrical contact between the electrodes, which would cause a short circuit and potentially lead to a lithium ion battery fire.

Most commercial separators are microporous polymer films, typically made from polyethylene (PE), polypropylene (PP), or multi-layer combinations of these materials. These materials are chosen for their chemical stability, mechanical strength, and thermal properties that help mitigate lithium ion battery fire risks.

A key safety feature of many polymer separators is their thermal shutdown mechanism. When exposed to elevated temperatures—such as those that might precede a lithium ion battery fire—PE separators begin to melt and close their pores around 130°C, while PP separators exhibit this behavior around 160°C. This pore closure restricts ion flow, effectively shutting down the battery before dangerous temperatures are reached.

Separator thickness, porosity, pore size distribution, and mechanical strength all influence battery performance and safety. Thinner separators reduce internal resistance but must maintain sufficient mechanical integrity to prevent short circuits that could cause a lithium ion battery fire. The optimal balance between these properties depends on the specific battery application and its safety requirements.

Ceramic-coated separators have gained popularity for their enhanced thermal stability and resistance to shrinkage at high temperatures. These separators typically feature a thin ceramic layer (alumina or silica) applied to one or both sides of a polymer base, providing improved safety margins and reducing lithium ion battery fire risks in demanding applications.

Non-woven separators, made from materials like polyimide or aramid fibers, offer higher temperature resistance than traditional polymer films, making them suitable for high-performance batteries where preventing lithium ion battery fire incidents is critical. These separators can withstand temperatures above 200°C without significant degradation.

The development of advanced separator technologies focuses on improving thermal stability, wettability by electrolytes, and mechanical strength while maintaining high ionic conductivity. These advancements play a crucial role in enhancing overall battery safety and reducing the potential for lithium ion battery fire events in various operating conditions.

Separator Types and Properties

| Type | Material | Shutdown Temp | Fire Risk |

|---|---|---|---|

| PE | Polyethylene | 130°C | Moderate |

| PP | Polypropylene | 160°C | Moderate |

| PE/PP/PE | Multi-layer | 130-160°C | Low |

| Ceramic Coated | Polymer + Ceramic | 130-160°C | Low |

| Non-woven | Polyimide/Aramid | >200°C | Low |

Separator selection directly impacts battery safety, with higher temperature tolerance significantly reducing lithium ion battery fire risk.

Other Materials

Beyond the four primary components, several Other Materials play essential roles in lithium ion battery construction and performance, including contributions to safety (a key focus of lithium ion battery check) and reducing lithium ion battery fire risks. These materials include current collectors, binders, conductive additives, thermal management materials, and casing components.

Current collectors serve as the electrical conductors between the electrodes and the external circuit. For cathodes, aluminum foil is typically used due to its corrosion resistance in high-voltage environments. Copper foil is the material of choice for anodes, offering high conductivity and stability in the lower voltage range. The thickness and surface treatment of these foils impact battery energy density and can influence thermal behavior related to lithium ion battery fire risks.

Binders are polymeric materials that hold electrode active materials and conductive additives together while adhering them to current collectors. Common binders include polyvinylidene fluoride (PVDF) for cathodes and styrene-butadiene rubber (SBR) with carboxymethyl cellulose (CMC) for anodes. Binder selection affects electrode mechanical stability and can influence thermal runaway propagation, a key factor in lithium ion battery fire incidents.

Conductive additives enhance the electrical conductivity of electrode materials, particularly for cathode materials with lower intrinsic conductivity. Carbon black, graphite, carbon nanotubes, and graphene are commonly used for this purpose. Proper distribution of conductive additives ensures uniform current flow, preventing hot spots that could contribute to lithium ion battery fire events.

Thermal management materials are increasingly important in battery designs, especially for large-format batteries in electric vehicles and energy storage systems. These materials include thermal interface materials, phase change materials, and heat-dissipating composites that help maintain optimal operating temperatures and prevent thermal runaway that leads to lithium ion battery fire incidents.

Battery casings provide mechanical protection and electrical insulation for the internal components. Materials range from aluminum and steel for rigid cases to flexible laminates for pouch cells. Casing design must balance weight, mechanical strength, and thermal management properties while providing a barrier that can contain potential lithium ion battery fire events and prevent the release of hazardous materials.

Sealants and adhesives ensure hermetic sealing of battery cells and modules, preventing electrolyte leakage and protecting against environmental contaminants. These materials must maintain their integrity across a wide temperature range and under mechanical stress, as failures can lead to short circuits and increased lithium ion battery fire risks.

Safety vents and pressure relief mechanisms are critical components in preventing catastrophic failures. These devices activate to release pressure and gases during abnormal conditions, reducing the risk of explosion and mitigating lithium ion battery fire severity. The materials used in these safety components must reliably function under extreme temperature and pressure conditions.

Supporting Materials and Their Functions

Current Collectors

Aluminum (cathode) and copper (anode) foils that conduct electricity while preventing short circuits that could cause lithium ion battery fire incidents.

Binders

Polymeric materials that maintain electrode structure integrity, contributing to overall battery stability and reducing lithium ion battery fire risks.

Conductive Additives

Carbon-based materials that improve electrode conductivity, preventing hot spots that could lead to lithium ion battery fire events.

Thermal Management

Materials that regulate temperature, critical for preventing thermal runaway and lithium ion battery fire incidents in high-performance applications.

Casings & Safety Features

Structural materials and safety mechanisms that contain components and mitigate lithium ion battery fire risks during abnormal conditions.

Addressing Lithium Ion Battery Fire Risks

While lithium ion batteries offer numerous advantages, addressing lithium ion battery fire risks remains a critical aspect of battery technology development. A lithium ion battery fire typically results from thermal runaway—a self-sustaining reaction where increasing temperatures cause battery components to break down and release flammable gases, leading to ignition.

Preventing lithium ion battery fire incidents requires a holistic approach involving material selection, cell design, thermal management, and protective mechanisms. Each component discussed in this guide plays a role in either reducing the likelihood of a lithium ion battery fire or mitigating its severity should one occur.

Advances in cathode materials, particularly the shift toward LiFePO₄ formulations, have significantly improved thermal stability and reduced lithium ion battery fire risks. Similarly, the development of non-flammable electrolytes and robust separators with reliable shutdown mechanisms has enhanced overall battery safety.

Beyond material improvements, battery management systems (BMS) play a crucial role in preventing lithium ion battery fire incidents by monitoring cell voltages, temperatures, and currents to prevent overcharging, over-discharging, and overheating. These systems can isolate problematic cells before conditions escalate to thermal runaway.

Ongoing research continues to focus on new materials and designs that further reduce lithium ion battery fire risks while maintaining or improving performance characteristics. From solid-state battery technologies to advanced thermal management systems, innovations across the battery ecosystem are working toward safer, more reliable energy storage solutions.

Conclusion

The performance, safety, and cost of lithium ion batteries are determined by the complex interaction of their constituent materials. From Cathode Materials that store and release energy to Separators that prevent short circuits, each component plays a vital role in battery operation.

As the demand for lithium ion batteries continues to grow across consumer electronics, electric vehicles, and energy storage applications, material innovation remains critical. Advancements in each material category—including those addressing lithium ion battery fire concerns—will drive improvements in energy density, cycle life, charging speed, and safety.Electronic shelf labels.

Understanding the properties and functions of Cathode Materials, Anode Materials, Electrolytes, Separators, and Other Materials provides a foundation for appreciating the complexity of lithium ion battery technology and the ongoing efforts to enhance its performance and safety profile, including reducing the potential for lithium ion battery fire incidents.Related Hydraulic Spare Parts.