1. Lithium Ion Battery Slurry Overview

Lithium ion battery slurry preparation—critical for batteries like the 18650 lithium ion battery—represents a key intermediate step in battery manufacturing, serving as the foundation for electrode performance. This complex process involves the homogeneous dispersion of active materials, conductive additives, and binders within a solvent to form a paste-like substance that will coat current collectors.

The quality of the slurry directly impacts key battery characteristics including energy density, power capability, cycle life, and safety. Even minor inconsistencies in slurry composition or dispersion can lead to significant performance degradation or failure. As the battery industry evolves toward higher performance and more sustainable solutions, the slurry preparation process continues to be refined, with increasing attention to environmental considerations that will later influence lithium ion battery disposal practices.

Modern slurry preparation requires precise control over multiple parameters: solid content, viscosity, particle size distribution, and homogeneity. These factors must be optimized for specific battery chemistries and applications, whether for consumer electronics, electric vehicles, or stationary energy storage systems.

The slurry preparation process bridges raw material processing and electrode manufacturing, making it a crucial link in the battery production chain. Innovations in this area often translate directly to improved battery performance while also addressing sustainability concerns that impact the entire lifecycle, including eventual lithium ion battery disposal.

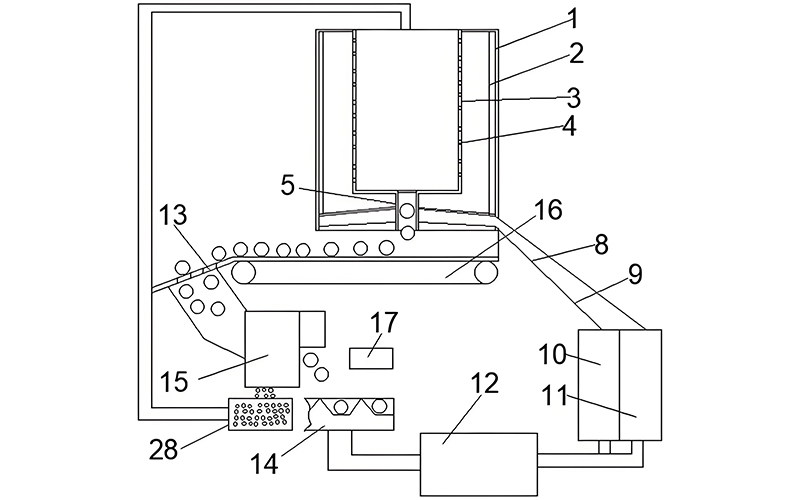

Slurry Preparation Workflow

The integrated process from raw material handling to homogeneous slurry formation, with quality control checkpoints that ensure consistency and performance while considering future lithium ion battery disposal implications.

2. Forces Acting on Particles in Suspension

In lithium ion battery slurry used in lithium ion battery cell, particles suspended in the liquid medium are subject to various interrelated forces that determine their dispersion behavior and ultimate distribution within the slurry matrix. Understanding these forces is essential for achieving the desired homogeneity and stability.

Van der Waals forces represent one of the primary interactive forces between particles, typically exhibiting attractive characteristics that can lead to agglomeration if unopposed. These forces arise from fluctuating dipole moments in adjacent particles and increase in strength as particle separation decreases.

Electrostatic forces often counteract Van der Waals attractions in aqueous slurries. When particles acquire a surface charge, they create an electrical double layer that generates repulsive forces between similarly charged particles. The balance between attractive and repulsive forces is described by the DLVO (Derjaguin-Landau-Verwey-Overbeek) theory, which provides a framework for predicting colloidal stability.

Steric hindrance becomes significant when polymer molecules or surfactants adsorb onto particle surfaces, creating a physical barrier that prevents close approach and reduces agglomeration. This mechanism is particularly important in non-aqueous battery slurries where electrostatic stabilization is less effective.

Hydrodynamic forces generated during mixing processes play a critical role in breaking up agglomerates and distributing particles uniformly. These forces must be carefully balanced—excessive shear can damage particle structures, while insufficient shear fails to overcome attractive forces.

Understanding these complex force interactions allows for the optimization of slurry formulations and processing conditions, resulting in more stable suspensions with better coating properties. This optimization not only improves battery performance but also contributes to longer battery life, indirectly reducing the frequency of lithium ion battery disposal.

Forces Acting on Suspended Particles

Balancing these forces is critical for achieving optimal slurry stability and homogeneity, which directly affects battery performance and longevity, thereby influencing lithium ion battery disposal rates through extended product lifespan.

3. Static Suspension Stability

Static suspension stability refers to a slurry's ability to maintain particle dispersion in the absence of external agitation. This property is crucial for battery manufacturing—where considerations like how to dispose of lithium ion batteries also matter—as slurries must remain stable during storage, transfer, and coating processes.

Sedimentation represents the primary challenge to static stability. According to Stokes' law, particle settling velocity depends on particle size, density difference between particles and medium, and medium viscosity. Larger particles and higher density differences accelerate sedimentation, while increased viscosity slows it.

Flocculation—loose aggregation of particles—can occur even without complete sedimentation, creating a network structure that alters slurry rheology. While some controlled flocculation may be beneficial for viscosity management, excessive flocculation leads to uneven coating and performance issues.

Thixotropy, the time-dependent reduction in viscosity under shear followed by recovery when shear is removed, is a desirable property in battery slurries. This characteristic allows for easier pumping and coating during shear application while maintaining stability during static periods.

Measurement techniques for static stability include sedimentation tests, centrifugation analysis, and multiple light scattering. These methods quantify particle migration rates and flocculation tendencies under controlled conditions.

Achieving optimal static stability often involves formulation adjustments such as adding thickeners, optimizing solid content, or modifying particle surface properties. These adjustments must balance stability requirements with other critical slurry properties like viscosity and coatability.

Enhanced static stability contributes to more consistent electrode production, reducing manufacturing waste and improving battery performance uniformity. This consistency not only enhances product quality but also supports more predictable end-of-life characteristics, facilitating more efficient lithium ion battery disposal and recycling processes.

Static Stability Comparison

- Stable suspension maintains uniform particle distribution

- Unstable suspension shows clear sedimentation and separation

- Optimal stability ensures consistent coating and performance

- Enhanced stability reduces material waste and supports sustainability efforts, including responsible lithium ion battery disposal

4. Lithium Ion Battery Slurry Preparation Principles

Lithium ion battery slurry preparation is governed by fundamental principles that ensure the formation of a homogeneous mixture with optimal properties for electrode manufacturing. These principles guide the selection of materials, equipment, and processing conditions.

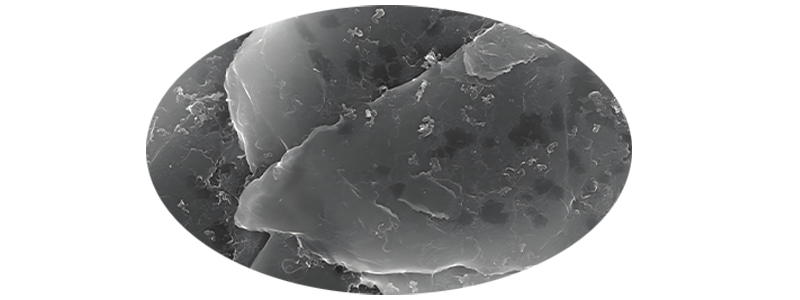

Dispersion uniformity forms the cornerstone of slurry preparation. Achieving complete dispersion involves breaking down agglomerates of active material particles while ensuring uniform distribution throughout the medium. This process requires sufficient energy input to overcome interparticle attractive forces without damaging individual particles.

Particle size control is critical, as particle dimensions influence surface area, packing density, and ultimately electrochemical performance. The preparation process must maintain or achieve the target particle size distribution through controlled milling or dispersion techniques.

Rheological optimization ensures the slurry has appropriate flow characteristics for coating. This involves balancing viscosity, yield stress, and thixotropic behavior to enable uniform application while preventing sagging or drying issues during processing.

Chemical compatibility must be maintained between all components—active materials, conductive additives, binders, and solvents. Incompatible materials can lead to undesirable reactions, phase separation, or binder degradation, compromising slurry stability and performance.

Process kinetics dictate the timing and sequence of material addition. Proper sequencing minimizes agglomeration and ensures complete wetting of all components, with sufficient mixing time allowed for each step to achieve equilibrium.

Energy efficiency has become an increasingly important principle, with modern processes designed to minimize energy consumption while maintaining dispersion quality. This not only reduces production costs but also aligns with broader sustainability goals that include responsible lithium ion battery disposal practices.

These principles collectively ensure that the resulting slurry will produce electrodes with uniform composition, optimal porosity, and consistent performance characteristics. Adherence to these fundamental principles also supports the production of batteries with more predictable lifespans and material compositions, facilitating more efficient lithium ion battery disposal and recycling at the end of their useful life.

Slurry Preparation Principles Framework

Key Interrelationships

The principles of slurry preparation are interconnected, with changes in one parameter affecting others. This complex relationship requires a systematic approach to optimization, considering both immediate performance and long-term sustainability including lithium ion battery disposal considerations.

5. Lithium Ion Battery Slurry Preparation Equipment

Specialized equipment is required to achieve the precise mixing, dispersion, and processing needed for high-quality lithium ion battery slurries. The selection of appropriate equipment depends on slurry composition, batch size, and performance requirements.

Planetary mixers are widely used for initial blending and premixing of components. These mixers utilize a rotating vessel combined with stationary or counter-rotating agitators to create complex flow patterns, ensuring initial homogeneity while minimizing air entrainment.

High-shear mixers employ rotor-stator configurations to generate intense mechanical forces that break down agglomerates. These machines are particularly effective for dispersing conductive additives and achieving initial particle separation, with adjustable shear rates to match material requirements.

Ball mills and bead mills use grinding media (typically zirconia beads) to apply compressive and shear forces, reducing particle size and improving dispersion. These devices are essential for processing high-viscosity slurries and achieving fine particle distributions, with precise control over media size and rotation speed.

Ultrasonic homogenizers utilize high-frequency sound waves to create cavitation, generating intense local shear forces that break down agglomerates. This technology is often used for final dispersion refinement or for processing heat-sensitive materials.

Continuous mixers are increasingly adopted in large-scale production, offering consistent processing with reduced batch-to-batch variation. These systems often combine multiple stages of mixing and dispersion in a single continuous process, improving efficiency and throughput.

Quality control equipment, including inline viscometers, particle size analyzers, and rheometers, plays a critical role in monitoring slurry properties during processing. This real-time data allows for immediate process adjustments, ensuring consistent quality.

Modern slurry preparation equipment incorporates advanced automation and process control systems, enabling precise parameter regulation and data logging. This level of control not only ensures product quality but also supports process optimization for reduced energy consumption and waste generation. These efficiency improvements contribute to the overall sustainability of battery production, complementing responsible lithium ion battery disposal practices to create a more circular battery economy.

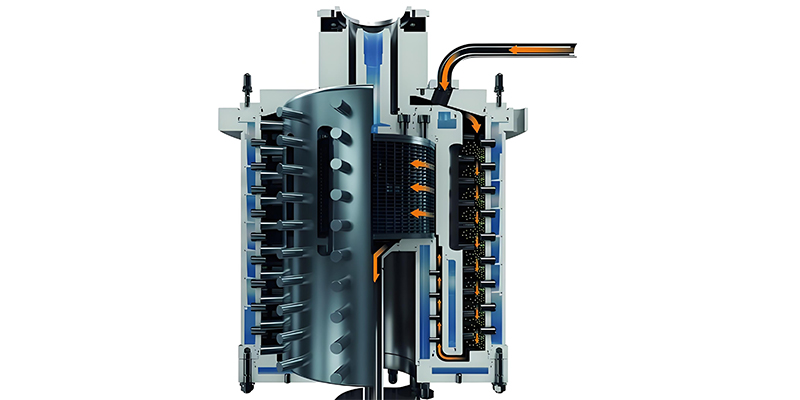

High-Shear Mixing Equipment

Critical for breaking agglomerates and achieving initial dispersion

Bead Mill System

Used for achieving precise particle size reduction and uniform dispersion

Quality Control Systems

Ensure consistent slurry properties and support process optimization, contributing to battery performance and eventual lithium ion battery disposal considerations

6. Lithium Ion Battery Slurry Preparation Process

The lithium ion battery slurry preparation process involves a series of carefully controlled steps designed to transform raw materials into a homogeneous mixture with precise characteristics. Each stage must be optimized to ensure final electrode performance.

Raw material preparation begins with the careful handling and preprocessing of all components. Active materials may undergo drying to remove moisture, which can affect slurry stability and battery performance. Conductive additives are often pre-dispersed to break up primary agglomerates before introduction to the main mixture.

Binder solution preparation involves dissolving or dispersing the polymer binder in the appropriate solvent. This step requires controlled temperature, mixing speed, and time to ensure complete dissolution without binder degradation. Proper binder preparation is critical for final electrode mechanical properties.

Premixing combines the active material, conductive additives, and a portion of the solvent in a planetary mixer. This initial blending creates a coarse dispersion, wetting the powder surfaces and preparing the mixture for more intensive dispersion steps.

Dispersion is the most critical stage, typically utilizing high-shear mixers or bead mills to break down remaining agglomerates. Process parameters including shear rate, residence time, and temperature are precisely controlled to achieve the target particle distribution and homogeneity.

Dilution adjusts the solid content to the precise level required for coating, typically by adding the remaining binder solution. This step must be performed gradually with continued mixing to maintain uniformity.

Deaeration removes entrained air bubbles that could cause defects during coating. This is often achieved through vacuum mixing or centrifugation, ensuring the slurry is free from voids that would compromise electrode integrity.

Quality control testing verifies key parameters including viscosity, solid content, particle size distribution, and homogeneity. Samples may also undergo rheological characterization to ensure coating suitability.

Slurry storage maintains the mixture under controlled conditions with gentle agitation to prevent sedimentation prior to coating. Temperature and humidity control during storage prevent viscosity changes and moisture absorption.

Throughout the process, strict process control and documentation ensure consistency between batches. Modern facilities employ automated systems to monitor and adjust critical parameters in real-time, minimizing variability. This level of process control not only ensures battery performance but also contributes to material efficiency, reducing waste and supporting sustainability initiatives. As the industry evolves, these processes are increasingly designed with consideration for the entire battery lifecycle, including material recovery during lithium ion battery disposal, to maximize resource utilization and minimize environmental impact.

Slurry Preparation Process Flow

-

1

Raw Material Preparation

Drying, sieving, and preprocessing of all components

-

2

Binder Solution Preparation

Controlled dissolution of polymer binders

-

3

Premixing

Initial blending of components to form coarse dispersion

-

4

Dispersion

High-shear processing to break agglomerates

-

5

Dilution & Adjustment

Final viscosity and solid content adjustment

-

6

Quality Control & Storage

Testing and controlled storage prior to coating, with considerations for material consistency that impact future lithium ion battery disposal processes

Sustainability Considerations in Slurry Preparation

As the lithium ion battery industry grows, sustainability considerations throughout the manufacturing process, including slurry preparation, have become increasingly important. These practices not only reduce environmental impact but also support more efficient lithium ion battery disposal and recycling.

Solvent recovery systems can capture and reuse organic solvents, reducing volatile organic compound emissions and raw material consumption. Water-based slurries, where compatible with battery chemistry, eliminate the need for hazardous organic solvents entirely.Electronic shelf labels.

Energy-efficient mixing equipment and optimized processing parameters reduce energy consumption during slurry preparation. Additionally, process improvements that minimize material waste contribute to overall resource efficiency, complementing end-of-life lithium ion battery disposal and recycling efforts to create a more sustainable battery lifecycle.Related Hydraulic Spare Parts.